Why Jerome Knitting Machines Are Recommended

In the field of knitting machine manufacturing, quality is of the utmost importance. Each component plays a vital role in ensuring the durability, efficiency and overall performance of the machine. We pride ourselves on quality machines and this is reflected in the careful selection of accessories that set our knitting machines apart from other machines on the market. In this article, we explore the unique characterist of other machine components, highlighting their exceptional quality and unparalleled advantages.

1. Special grade and harder Screws:

Our knitting machines are reinforced with harder screws and are designed to withstand rigorous handling without damage. The enhanced durability of these screws ensures longevity and stability, helping to improve the overall sturdiness of our machines.

2. Customized Selector:

Our machine needle selectors are specially customized and use high-quality round wire. The price is 5-6 times more expensive than ordinary flat wire, and the service life will be longer.

3. Thicker Belts increase stability:

Unlike traditional belts, our belts have increased thickness to ensure stability during machine operation and will not break due to long-term friction.

4. High-speed steel (HSS) cutting technology for precision parts:

Precision is crucial in sock machine manufacturing, and our commitment to excellence is reflected in our use of high-speed steel cutting technology for components such as Down Picker, Up Picker and Spinning Plate. This cutting-edge technology produces superior-quality parts, allowing machines to run smoother and increase efficiency.

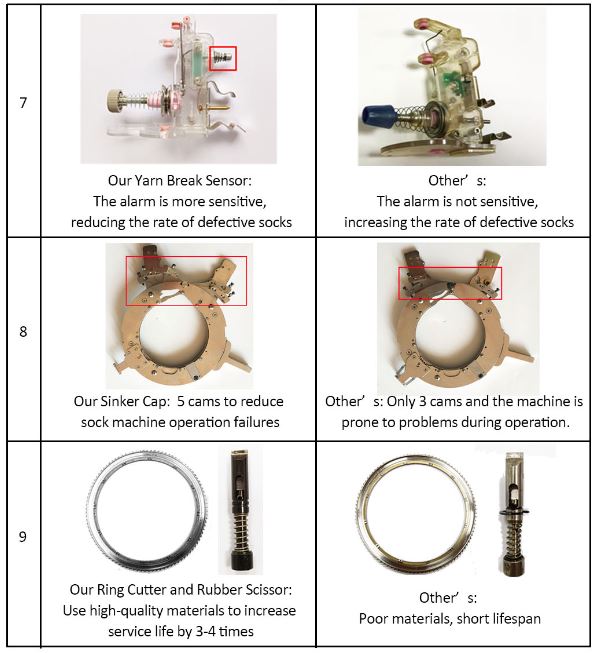

5. The upgraded Yarn Break Sensor improves sensitivity:

Our knitting machine is equipped with an upgraded yarn break sensor that will be more sensitive in detecting yarn breaks. Minimize downtime and reduce the incidence of defective products.

6. The sixth generation five cams Sinker Cap:

Our sixth generation sinker cap features an innovative 5 cams design that optimizes the smoothness of the knitting process and minimizes potential problems. This advanced feature goes beyond traditional designs that typically include only 3 blades.

7. New materials for Ring Cutter and Rubber Scissors:

The new material Cr12MoV is used in our ring cutter and rubber scissors, which greatly extends their service life, 3-4 times that of traditional materials. This durability not only reduces replacement frequency but also ensures continued efficiency and reliability.

From screws to selectors, sinker caps to alarms, every accessory is carefully researched to enhance performance, durability and overall quality. If you have any questions about the machine or the process of making products, you can contact us. We can also share our customer entrepreneurship cases and experiences. Choosing us not only ensures that you get high-quality machines, but also professional services, giving you a pleasant experience.